What is Blown-in-blanket (BIBS) insulation?

Blown-in insulation also known as loose-fill insulation is the process of filling cavities and covering places like attic floors and hard to reach places. Loose-fill insulation materials have a good R-value. There are different loose-fill materials available to use for this process, from styrofoam pellets to loose fibreglass fibres and the the material that is more commonly used cellulose insulation.

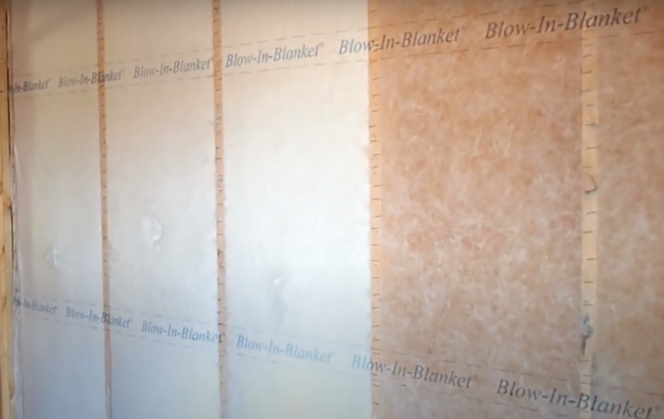

One way blown-in insulation works is, first a very thin mesh like blanket is installed over the cavity of the desired area and stapled into place, then a small hole is cut into the blanket and the tube which injects the insulation is inserted into the hole and a blowing machine blows and delivers the insulation into the cavity.

Blown-in insulation is a good option for adding insulation to attics and walls and other tight and hard to reach spaces.

Homeowners benefit from this type of application in many ways. Modern houses are bigger and more complex. A significant percentage of wall cavities contain obstructions such as plumbing and electrical wiring, making it difficult to use traditional insulation methods to insulate new homes.

By preparing the insulation system at the construction site, we can insulate those difficult areas in homes more effectively and efficiently. Loose fill method is compatible with nonstandard wall framing, floor, and ceiling framing. The method fills cavities completely, eliminating any gaps and voids. As well as achieving higher R-values, this method also enhances sound control properties.

One way blown-in insulation works is, first a very thin mesh like blanket is installed over the cavity of the desired area and stapled into place, then a small hole is cut into the blanket and the tube which injects the insulation is inserted into the hole and a blowing machine blows and delivers the insulation into the cavity.

Blown-in insulation is a good option for adding insulation to attics and walls and other tight and hard to reach spaces.

Homeowners benefit from this type of application in many ways. Modern houses are bigger and more complex. A significant percentage of wall cavities contain obstructions such as plumbing and electrical wiring, making it difficult to use traditional insulation methods to insulate new homes.

By preparing the insulation system at the construction site, we can insulate those difficult areas in homes more effectively and efficiently. Loose fill method is compatible with nonstandard wall framing, floor, and ceiling framing. The method fills cavities completely, eliminating any gaps and voids. As well as achieving higher R-values, this method also enhances sound control properties.

|

Cellulose insulation

Cellulose insulation is made from a mixture of wood and cardboard and recycled paper materials. Once the cellulose is processed it is then treated with boric acid along with other elements to make it flame-resistant and give it mould-resistant properties. |

|

Fibreglass insulation

Fibreglass insulation is made from melted glass that is blown or spun into fibres. The majority of fibreglass on the market is made from 40-50% recycled glass. Blown-in fibreglass is a better option than traditional fibreglass batt insulation and has proven to be more effective by up to 50%. When installed properly. Blown-in fibreglass (BIBS) has a high R-value, and the insulation does not settle over time. BIBS has great coverage and will not have any voids. |

Blown-in blanket aka BIBS

Blown-in blanket aka BIBS

BIBS- Blown in Blanket System-

A mesh like material is stapled over a cavity and filled through a small hole with a blowing machine.

A mesh like material is stapled over a cavity and filled through a small hole with a blowing machine.